Model No. DLB-R300 Letterpress Machine Intermittent typeHigh

Model No. DLB-R300 Letterpress Machine Intermittent type

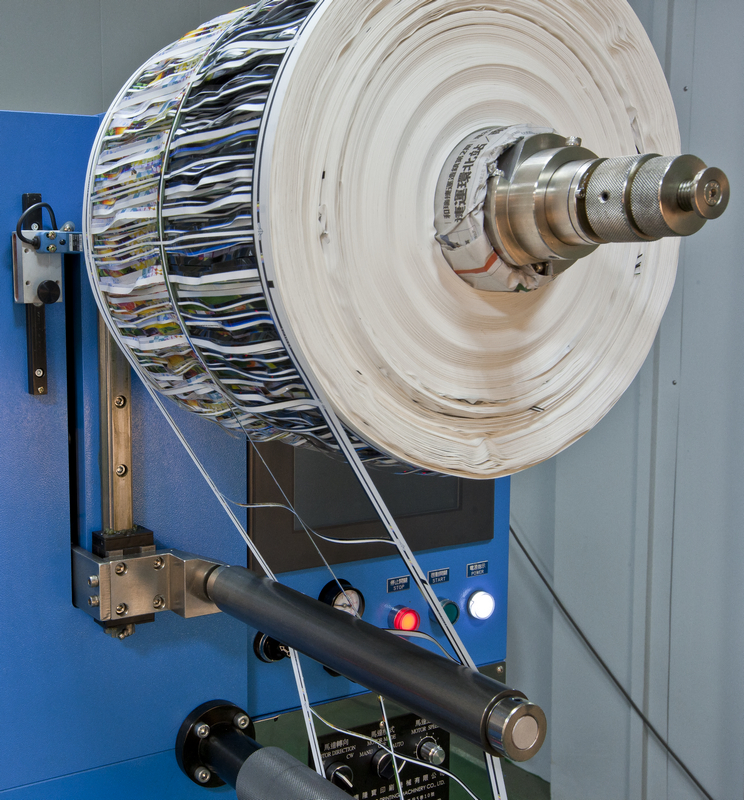

High Speed Rotary Label Printing Machine

Key Features:

Well-designed man-machine interface, simple and smooth programming and selection of high – expansion image

To view the system can easily master the printing precision and effect to facilitate the adjustment of the operator,

You can save on paper waste and to control the printing quality.

The servo un winder suction roller and pressure roller device, in accordance with the need sofa variety of printed

materials, you can use both the suction and pressure roller can also be individually pull the paper .

Servo un winder using a continuous feed, with a unique in termite entre tum to the tension control, there will be no

paper to stop feeding frustrated phenomenon.

Color adjustment accuracy E+L edge of the paper correction device correcting the paper to reduce paper distorted, thus ensuring the quality of printing.

The color adjustment applications servo motor control, the minimum fine – tuning the amount of 0.01mm. In operation around easily operate to adjust.

Exclusive impression adjustment device can be synchronous lifting impression point, unilateral fine- tuning of

synchronized upper and lower pressure level impression design is simple and fast but also accurate.

Color adjustment accuracy E+L edge of the paper correction device correcting the paper to reduce paper distorted, thus ensuring the quality of printing.

Reducing set-up times and material waste.